the secret that you do not know about SiMn series

What are ferrosilicon and silicomanganese?

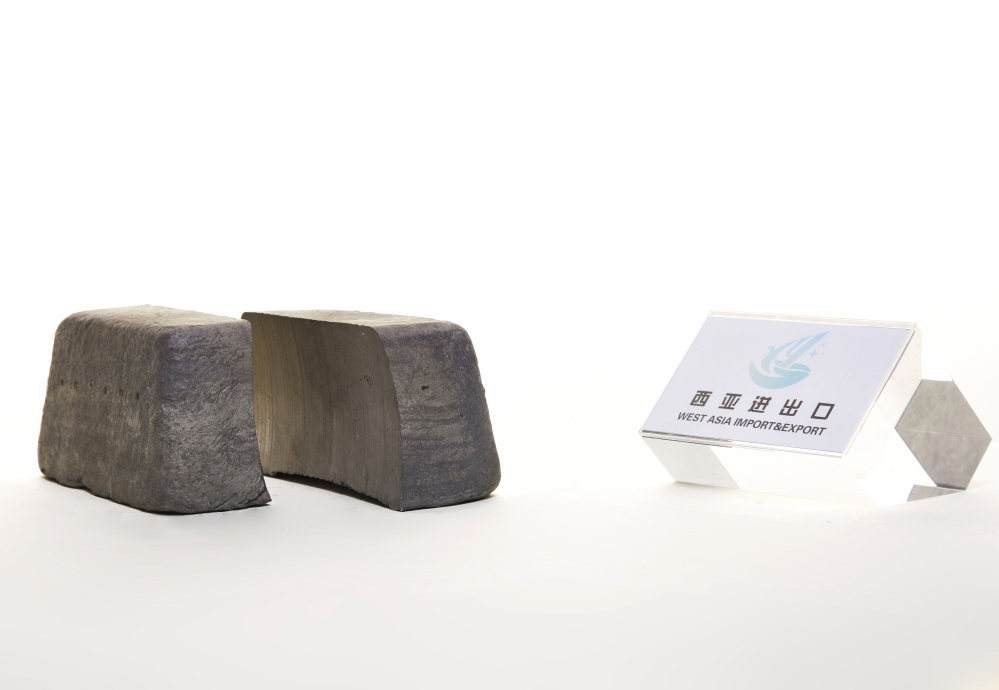

Silicon manganese is a kind of iron alloy. According to the classification of its main elements, ferroalloys can be divided into different series such as silicon series, manganese series, and chromium series.

Ferrosilicon and silicomanganese use

Ferrosilicon and silicomanganese are the most commonly used ferroalloys in the steelmaking process. Its main use is as a deoxidizer and alloying agent in steelmaking. It is used to eliminate excess oxygen and sulfur in molten steel and improve the quality and performance of steel.

In recent years, the proportion of ferrosilicon and silicomanganese alloys in consumption has undergone great changes. Because silico-manganese alloy can not only deoxidize, but also increase the manganese content in steel and improve the strength of steel, the proportion of silico-manganese alloy used as deoxidizer is gradually higher than that of ferrosilicon. In addition to steel making, another important use of ferrosilicon is to smelt magnesium.

Silicon can significantly improve the elasticity and magnetic permeability of steel. Therefore, silicon alloys must be used when smelting structural steel, tool steel, spring steel and silicon steel for transformers. Normal steel contains 0.15%-0.35% silicon. Silicon content in structural steel is 0.40%-1.75%. The silicon content in tool steel is 0.30%-1.80%. Silicon content in spring steel is 0.40%-2.80%. The silicon content of stainless acid-resistant steel is 3.40%-4.00%. The heat-resistant steel contains 1.00%-3.00% silicon. Silicon steel contains 2%-3% silicon or more.

Manganese can reduce the brittleness of steel, improve the hot workability of steel, and increase the strength, hardness and wear resistance of steel. "No manganese cannot make steel", the manganese consumed by the steel industry accounts for more than 90% of its output. Manganese is an indispensable functional basic raw material for the production of high-quality steel. In the steelmaking process, impurities such as sulfur and oxygen can be removed, and the physical properties of the steel can be improved by improving the strength, hardness and wear resistance. At present, the role of manganese in the steel production process has no other elements to replace.

Production method of silicomanganese series

According to the used smelting equipment, operation method and heat source, it can be roughly divided into electric furnace method, thermite method and others. Among them, the electric furnace method is the main method of producing ferroalloys, and its output accounts for about 80% of all ferroalloys. The main equipment used is electric furnaces.

Ferrosilicon and manganese silicon production costs

The production cost of ferrosilicon is mainly composed of electricity, silica and blue carbon. Among them, electricity accounts for the largest proportion of the production cost of ferrosilicon, accounting for about 60-70%. Blue charcoal is about 25-30%. The price of silica is cheap, and the cost ratio is very low, about 2%.

The production cost of silico-manganese alloy is mainly composed of manganese ore, electricity and coke. Among them, manganese ore accounts for about 60%, electricity costs about 20%-25%, and coke about 10%-15%.