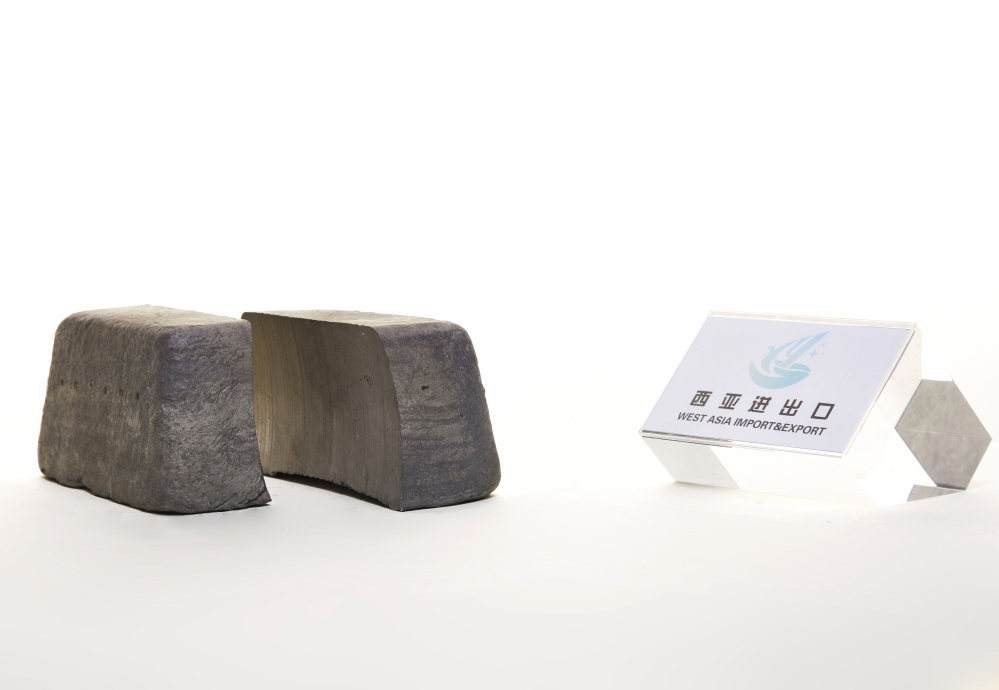

the difference between HC ferrochrome and MC ferro chromium

When it comes to high-carbon ferrochrome and low-carbon ferrochrome, we have to start with ferrochrome. Ferrochromium is an iron alloy with chromium and iron as the main components. It is one of the main alloying agents used in the steel industry.

Ferrochrome has high hardness and good wear resistance. The addition of chromium to steel can significantly improve the oxidation resistance of steel. Increase the corrosion resistance of steel.

Ferrochrome contains 55%-75% chromium. According to different carbon content, ferrochrome can be divided into high-carbon ferrochrome, medium-carbon ferrochrome, low-carbon ferrochrome and micro-carbon ferrochrome. So how are they different?

High-carbon ferrochrome contains 4-10% carbon, medium-carbon ferrochrome contains 0.5-4% carbon, low-carbon ferrochrome contains 0.15-0.5% carbon, and micro-carbon ferrochrome contains less than 0.15% carbon.

The smelting methods of micro-carbon ferrochromium include electric silicon heating method, hot exchange method, etc.

Mainly used to improve the oxidation resistance and corrosion resistance of steel. Make the surface of the steel form an oxide film with strong adhesion in an oxidizing atmosphere. Then the oxidation stops or the oxidation speed slows down. Micro-carbon ferrochrome is mainly used to produce stainless steel, wear-resistant and heat-resistant steel.

The main uses of high-carbon ferrochrome (carbon ferrochrome) are:

1. Used as an alloying agent for high-carbon circulating bead steel, tool steel and high-speed steel. Improve the hardenability of steel, increase the wear resistance and hardness of steel.

2. Used as an additive for cast iron. Improve the grindability and hardness of cast iron. At the same time, cast iron has good heat resistance.

3. The slag-free method is used to produce silicon-chromium alloys and medium, low and micro-carbon ferrochromium and chromium-containing raw materials.

4. Produce chromium-containing raw materials for metallic chromium by electrolysis.

5. Used as raw material for smelting stainless steel by oxygen blowing method.

The smelting process of high-carbon ferrochrome: The smelting methods of high-carbon ferrochrome include blast furnace method, electric furnace method, plasma method, smelting reduction method, etc.