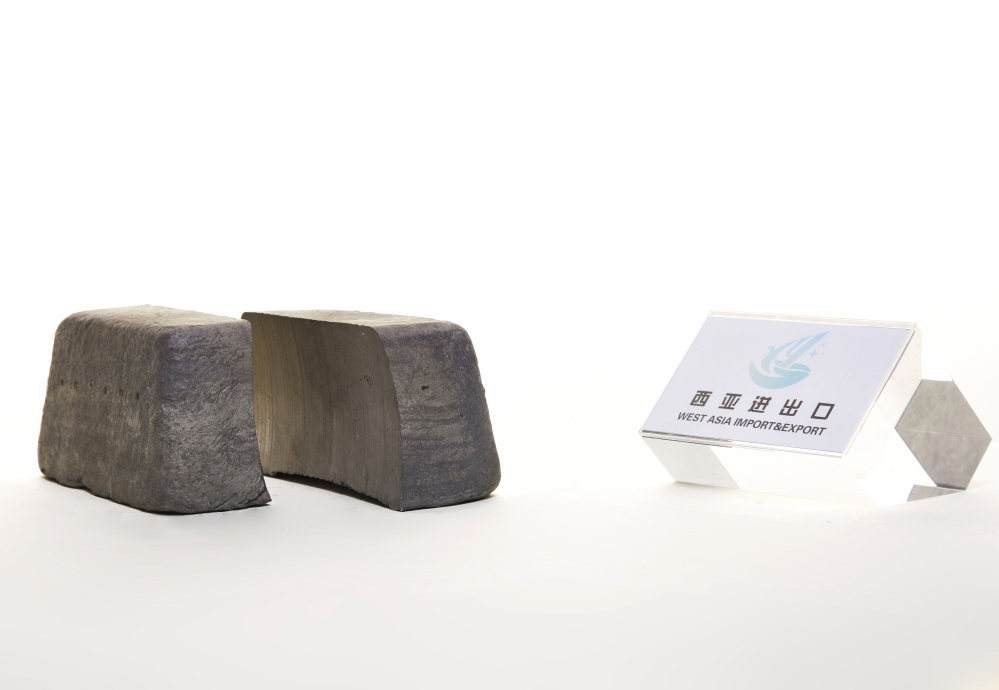

Ferro Silicon

Ferro silicon is widely used in the steel industry, foundry industry and other industrial production.

- Grade: Fesi 65/70/72/75 etc.

- Size: 10-50mm.50-100mm

Ferro silicon is made by smelting coke, steel scraps, and quartz (or silica) in a submerged arc furnace. Commonly used ferro silicon grades are Fesi70%, FeSi72%, FeSi75%.

Ferro Silicon Uses

1. Ferrosilicon is an essential deoxidizer in the steelmaking industry. In steelmaking, ferrosilicon is used for precipitation deoxidation and diffusion deoxidation. Brick iron is also used as an alloying agent in steelmaking.

2. Used as inoculant and nodulizer in cast iron industry. In the production of ductile iron, ferrosilicon is an important inoculant (to help precipitate graphite) and nodularizer.

3. Used as reducing agent in ferroalloy production. Not only the chemical affinity between silicon and oxygen is great, but also the carbon content of high silicon ferrosilicon is very low. Therefore, high-silicon ferrosilicon (or silicon alloy) is a reducing agent commonly used in the production of low-carbon ferroalloys in the ferroalloy industry.

4.75# ferrosilicon is often used in the high-temperature smelting process of metal magnesium in the Pidgeon method of magnesium smelting to replace the magnesium in CaO. Production plays a big role.

5. Other uses. Finely ground or atomized ferrosilicon powder can be used as a suspension phase in the mineral processing industry.

6. It can be used as a coating for welding rods in the welding rod manufacturing industry. High-silicon ferrosilicon can be used in the chemical industry to make products such as silicone.

Grade | Chemical Composition (%) | ||||||

Si% | Al% | Ca% | P% | S% | C% | Fe% | |

≥ | ≤ | ||||||

FeSi75 | 75 | 1.5 | 1 | 0.035 | 0.02 | 0.2 | Balance |

FeSi72 | 72 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance |

FeSi70 | 70 | 1.5 | 1 | 0.04 | 0.02 | 0.2 | Balance |

FeSi65 | 65 | 2 | 1 | 0.04 | 0.02 | 0.2 | Balance |