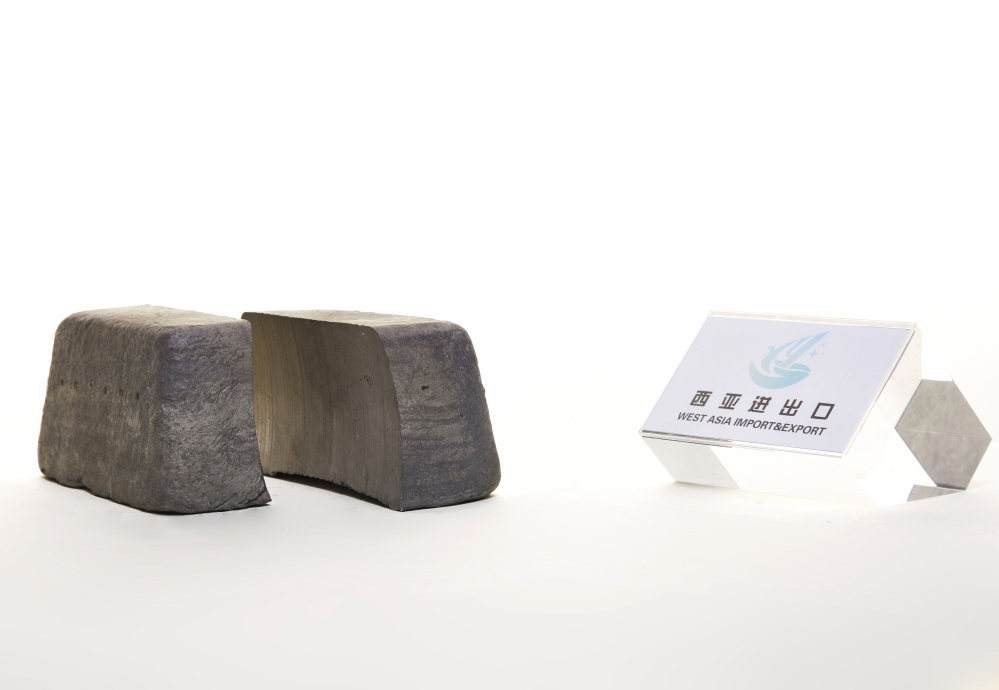

Ferro chrome

Ferrochrome is ferroalloy with chromium and iron as the main components. It is one of the main alloying agents used in the steel industry. In addition to the main components of chromium and iron, it also contains impurities such as carbon, silicon, sulfur, and phosphorus.

- Grade: HCFeCr 62.0-72.0, C≤10 LCFeCr63.0-75 C≤4 MCFeCr C≤0.15

- Size: 3-10mm 10mm-80mm 150mm-200mm

Ferrochromium contains 55% to 75% chromium, and is divided into high carbon (4% to 10% C), medium carbon (0.5% to 4% C), low carbon (>0.15% to 0.5% C) and Micro-carbon (≤0.15%C) ferrochromium. High carbon ferrochromium is also called carbon ferrochromium, and medium, low and micro-carbon ferrochromium is also called refined ferrochromium. A high-carbon ferrochromium produced from chrome ore with a low chromium-to-iron ratio, containing 50% to 55% of Cr is called charge grade ferrochromium, and nitrogen-containing ferrochromium containing N2% to 10% is used as a nitrogen alloying agent. It is called ferrochromium nitride. What are the three grades of micro-carbon ferrochromium (V10) (V6) (V3) The carbon content of the three grades is (0.1)% (0.06)% (0.03)%。

Grade | Chemicals(%,≥,≤) | ||||||

Cr | C | Si | P | S | |||

Range | Ⅰ | Ⅰ | Ⅰ | Ⅱ | |||

Micro Carbon | FeCr69C0.03 | 63.0-75.0 | 0.03 | 1 | 0.03 | 0.025 | — |

FeCr69C0.06 | 63.0-75.0 | 0.06 | 1 | 0.03 | 0.025 | — | |

FeCr69C0.10 | 63.0-75.0 | 0.1 | 1 | 0.03 | 0.025 | — | |

FeCr69C0.15 | 63.0-75.0 | 0.15 | 1 | 0.03 | 0.025 | — | |

Low Carbon | FeCr69C0.25 | 63.0-75.0 | 0.25 | 1 | 0.03 | 0.025 | — |

FeCr69C0.50 | 63.0-75.0 | 0.5 | 1 | 0.03 | 0.025 | — | |

FeCr69C1.0 | 63.0-75.0 | 1 | 1 | 0.03 | 0.025 | — | |

FeCr69C2.0 | 63.0-75.0 | 2 | 1 | 0.03 | 0.025 | — | |

FeCr69C4.0 | 63.0-75.0 | 4 | 1 | 0.03 | 0.025 | — | |

High Carbon | FeCr69C6.0 | 62.0-72.0 | 6 | 1 | 0.03 | 0.04 | 0.06 |

FeCr69C9.5 | 62.0-72.0 | 9.5 | 1 | 0.03 | 0.04 | 0.06 | |

Ferro chrome uses

1. LcFeCr mainly used to produce stainless steel, acid-resistant steel and heat-resistant steel.

2. It mainly used as steel making alloying additives, used in steel making refining later joined.

3. FeCr can used as alloy agent to improve the hardenability of steel and increase the wear resistance and hardness of steel.

4. It used as the additive of cast iron to improve the abrasion resistance and hardness of cast iron.