Email

info@wasiatrade.com

Phone+86 16689780979

- Home

- Product

- Export - Metals

- Plastisol

- Ferro Silicon

- Deoxidizer

- Ferromolybdenum

- Chromium Metal

- Ferrotitanium

- Ferrovanadium

- Aluminum ingot

- Magnesium ingot

- Dysprosium-Ferro

- Calcium Silicon

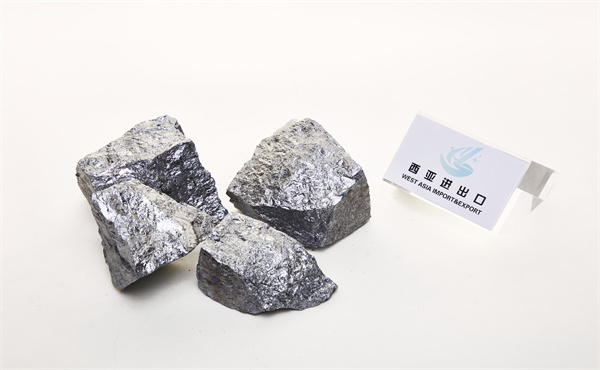

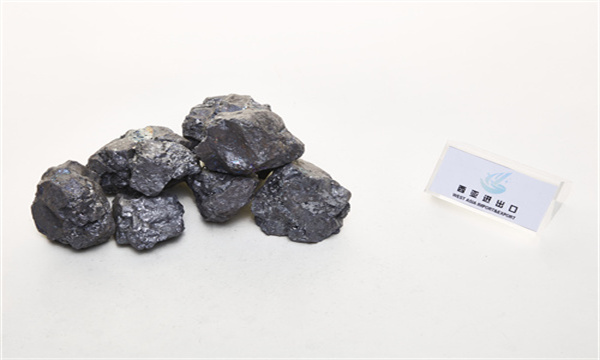

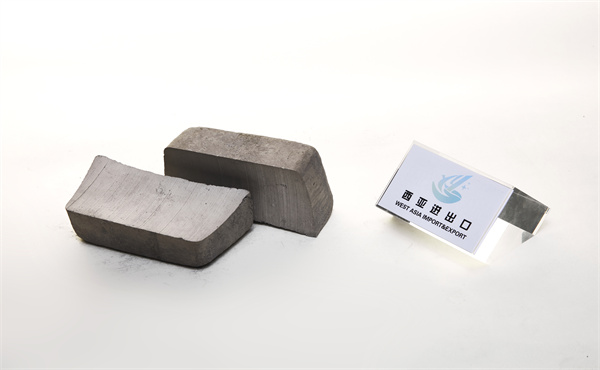

- Silicon Metal

- Cored Wire

- silicon manganese

- Recarburizer

- High Carbon Silicon

- Electrolytic Manganese Flakes

- Silicon slag/Low carbon silicon

- Ferro chrome

- Silicon calcium manganese

- Ferro Manganese

- Nodulizer

- Silicon barium

- Silicon powder /Micro Silicon-Powder

- Ferro Silicon Aluminum

- Silicon aluminum barium calcium

- Chromium silicon

- Silicon Carbide

- Silicon barium calcium

- Inoculant

- Silicon briquette

- Silicon aluminum barium

- Export - Metals

- About us

- Service

- FAQ

- News

- Contact