What is Refining slag

Refining slag refers to the technology used after mixing raw materials in a certain proportion and particle size, heating them below the melting point of the raw materials, sintering the raw materials together, and then crushing them into particle sizes. The main components are CaO-CaF2 base, CaO-Al2O3 base and CaO-Al2O3-SiO2 base.

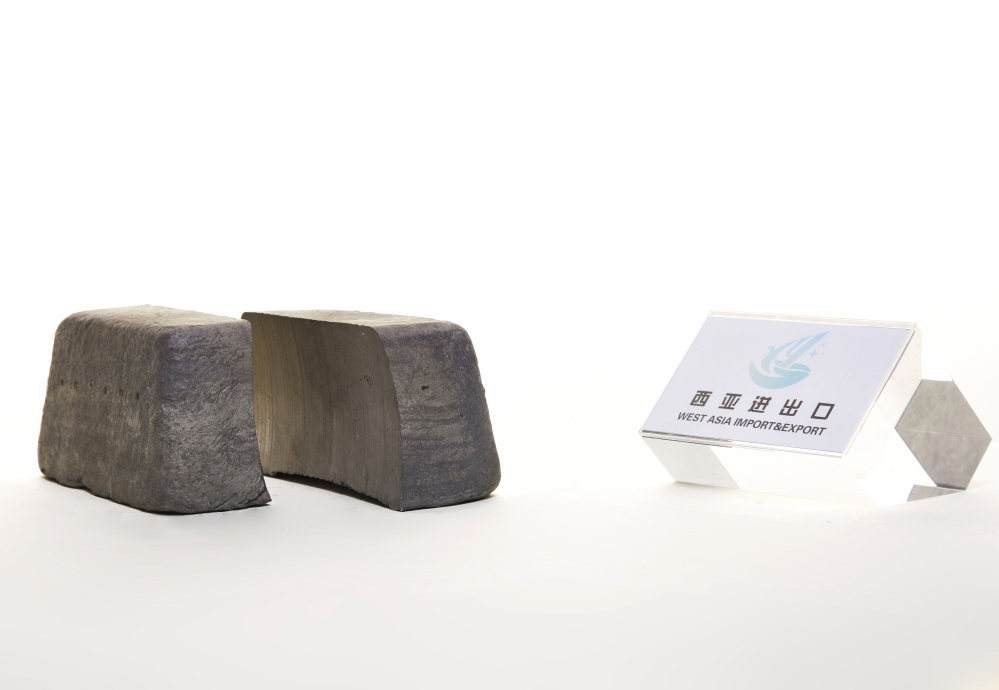

3 different Refining slag

.jpg)

Pre-smelting slag Sintering refining slag Composite refining slag

Performance of Refining slag

The main components of refining slag are calcium aluminate, alumina, silicon oxide, calcium fluoride, magnesium oxide, etc. These metal ions are combined into calcium oxide-calcium fluoride base, calcium oxide-alumina base, calcium oxide-alumina-silica base; the composite material formed is refining slag. Refining slag is a necessary additive for deoxidation and desulfurization in the refining process of steel companies.

Characteristics of Refining slag

Refining slag has the advantages of uniform chemical composition, low melting point, fast melting speed, reduced refining power consumption, and short refining time. It has attracted more and more attention from steel companies and is currently one of the more important steel making additives.

Uses of Refining slag

Before attacking, the refining slag is put into the ladle, because the molten steel flows into the ladle from the upper layer, the molten steel and the refining slag are vigorously stirred, the refining slag quickly melts into the molten steel, and then aggregates and floats. Due to the strong reducibility of refining slag, it has strong deoxidation and desulfurization capabilities, which can remove oxygen and sulfur impurities in molten steel during the mixing process of molten steel. At present, the desulfurization capacity of refining slag can reach 85%

| CaO | A2LO3 | SiO2 | Fe2O3 | MgO | P | TiO2 |

| 47-52 | 38-42 | ≤2.5 | ≤1.0 | 1.0 | 0.05 | ≤1 |

| 45-50 | 37-45 | 2-5 | ≤1.5 | 3-5 | 0.05 | ≤1 |

| 47-55 | 50-55 | 6-8 | ≤1.5 | 1.0 | 0.05 | ≤1 |

| 30-35 | 50-55 | ≤2.0 | ≤0.1 | |||

| ≥50 | ≥30 | ≤1.5 | ≤0.1 | 0.15 |