Indian silicon manganese manufacturers forced to reduce production

Hainan West Asia Ferroalloy Group recently learned that the rise in electricity prices in Andhra Pradesh, India, had a negative impact on the silicon manganese manufacturers. Against the background of sluggish demand for manganese alloys and falling prices in the international market, the growth of production costs is forcing manufacturers to reduce production or even stop production altogether.

After the Andhra Pradesh Electricity Regulatory Commission (APERC) approved to increase the electricity price from April 1, 2023, the local manganese alloy manufacturers found themselves in trouble. According to comments from local producers, a 20% increase in electricity prices may reach 7.9 rupees per kilowatt hour (0.097 US dollars per kilowatt hour). Considering the high energy consumption in the production process, electricity accounts for up to 60% of the cost structure, and the increase in production costs leads to a decrease in the profitability of this type of product.

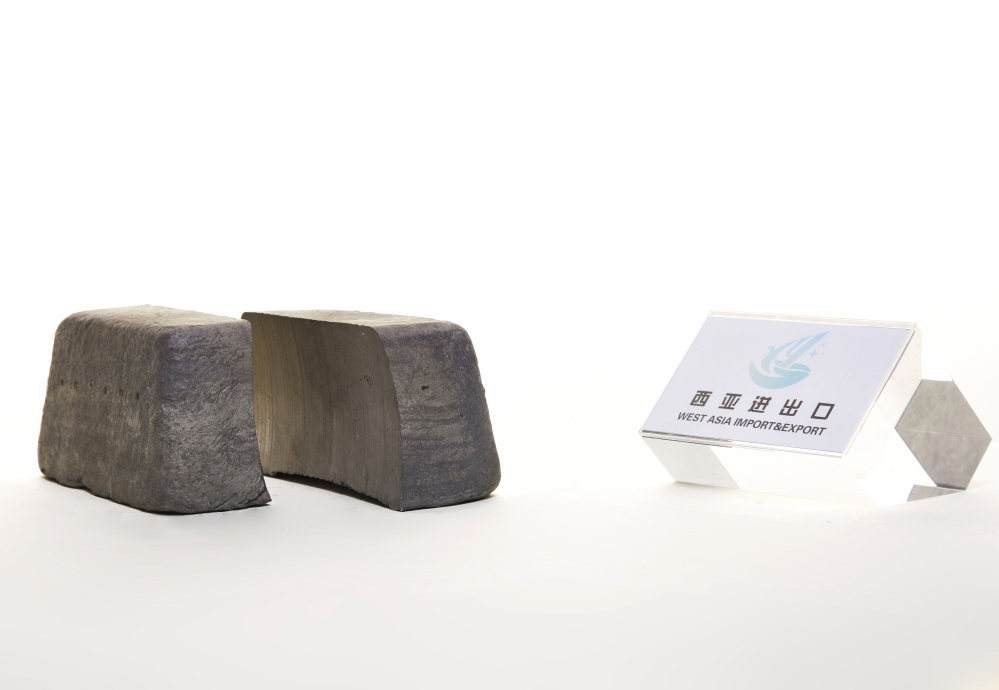

According to the data surveyed by Hainan West Asia Laminating Machine Group, the production cost of silicon manganese (65% Mn; 16% Si) in Andhra Pradesh in April exceeded US $1050 EXW, while the quotation of silicon manganese (65% Mn; 16% Si) in India declined to US $980-1010 FOB due to sluggish demand.

In the current situation, many manufacturers have to reduced their production of manganese alloys. Meanwhile, large manufacturers still operating are considering the possibility of a complete shutdown.

According to previous reports, the manufacturer has requested the regulatory authorities to modify tariffs, but as of now, the enterprise has not received a response.