How did metal silicon come from?

Silicon metal, also known as industrial silicon or crystalline silicon, is usually produced by reducing silicon dioxide with carbon in an electric furnace. Its main use is as an additive to non-ferrous alloys and as a starting material for the production of semiconductor silicon and organic silicon.

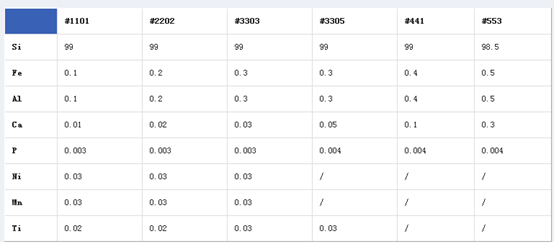

In my country, silicon metal is usually classified according to the content of three main impurities: iron, aluminum and calcium. According to the percentage content of iron, aluminum and calcium in metal silicon, metal silicon can be divided into different grades such as 553, 521, 441, 421, 411, 3305, 3303, 2502, 2202, 1501, 1101 and so on.

Silicon metal can affect every aspect of our life, so where did silicon metal come from?

Let's take a look at the production process of silicon metal.

step.1

After the raw silica is washed, screened and dried, according to the type of reducing agent used, the ingredients are mixed in different proportions, and the proportion of each material is controlled by a computer program, and they are collected from the silo on a belt and mixed through the feeding process. Evenly, into the electric furnace; the high degree of automation and large-scale feeding process is carried out continuously.

step.2

An electric current is passed on the electrode to heat the material in the brain, reaching a high temperature of over 1800 degrees Celsius. Silicon is reduced in the brain and is in a liquid state. It is released through the silicon outlet and cast into silicon ingots, which are crushed and packaged into industrial silicon. powder sale.

step.3

The oxygen and air mixed bottom blowing method is adopted. The bottom blowing oxygen permeable brick is installed in the bottom of the bag. There are many thin copper tubes in the permeable brick. Oxygen and air are blown from the thin copper tubes to the silicon melt for refining. After the oxygen blowing is over, a positive pressure is also formed in the silicon melt through the air-permeable brick. The refining process requires stirring, which uses compressed air to stir, the purpose of which is to improve the kinetic conditions of the slag-metal element phase reaction, accelerate slagging, remove impurities as soon as possible, and reduce heat loss and silicon liquid sticking.

At present, the production process route of the carbothermal method for the production of silicon metal in China: silica is generally used as raw material, petroleum coke, charcoal, wood chips, low ash coal, etc. Silicon metal reduced, which is a slag-free submerged arc high-temperature melting process.

Although silicon metal is extracted from silica, the raw material used for silicon metal is quartz sand used in industrial production, and it has undergone multi-step reactions to complete the transformation from sand to silicon metal .

If you need more information, please contact Hainan West Asia Import and Export Group Co., Ltd., we can provide you with high-quality products and best prices.