Commonly used steelmaking deoxidizer.

In the field of steelmaking, high oxygen content will reduce the ductility, impact toughness and fatigue damage resistance of the metal, and reduce the corrosion resistance of the metal. Therefore, deoxidation treatment should be carried out in the later stage of steelmaking.

Hainan West Asia Group has classified several commonly used deoxidizers.↓↓↓

1. Ferro Silicon: The main components of ferrosilicon are iron and silicon. It is a deoxidizer commonly used in steelmaking and casting. The chemical affinity between silicon and oxygen is very large, which can effectively convert oxygen into dioxide Silicon, adding a certain amount of silicon to steel can effectively improve the strength, hardness and elasticity of steel.

.png)

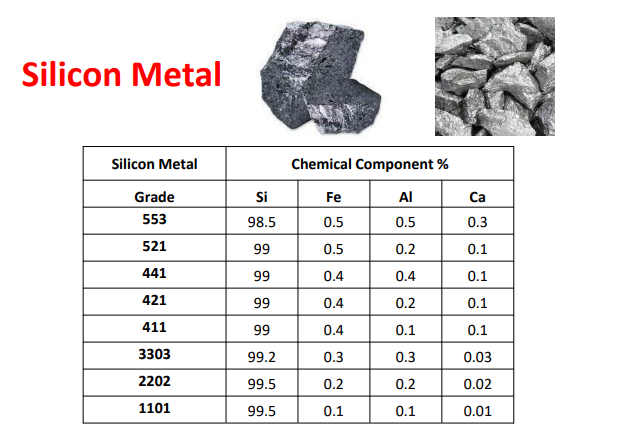

2. Silicon metal: Silicon metal is also a commonly used steelmaking deoxidation material, which can effectively remove oxygen from molten steel, and reduce the reaction ability during smelting while deoxidizing, making deoxidation safer.

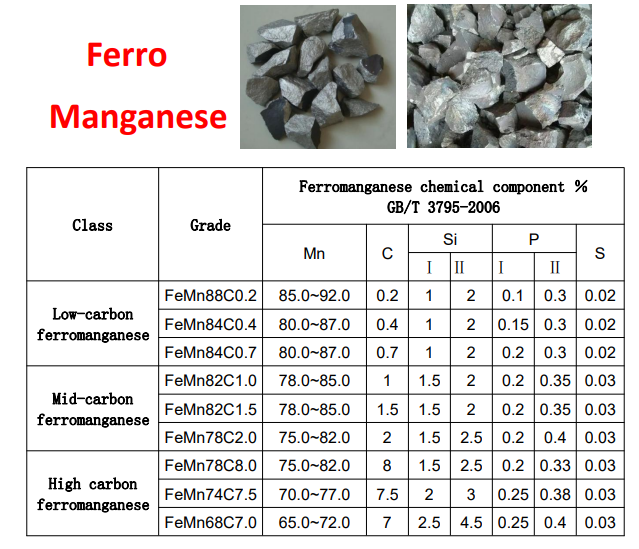

3. Ferromanganese: The main components of ferromanganese are manganese and iron. Ferromanganese is often used as a casting deoxidizer, desulfurizer and alloy additive. Using ferromanganese as a steelmaking material can effectively deoxidize and improve the hardness and durability of steel.

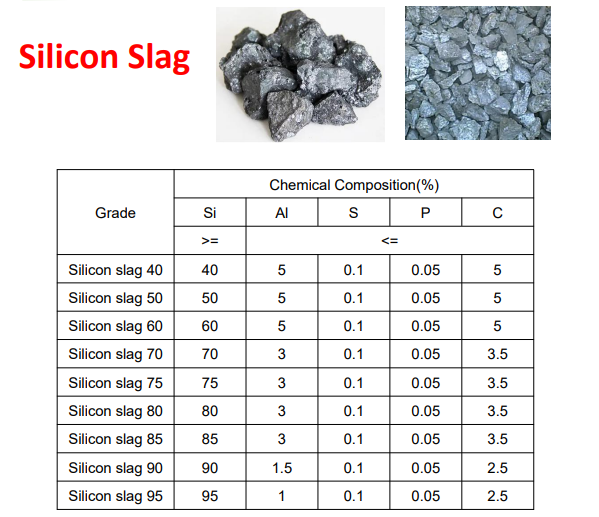

4. Silicon slag: Silicon slag is the bottom slag produced by smelting ferrosilicon and metal silicon, which still contains a certain amount of silicon. Silicon slag can be used as a deoxidizer for steelmaking, and can also be purified again to produce high-silicon content. Ferroalloy products can effectively reduce the cost of steelmaking and improve the efficiency of manufacturers and product quality.

5. Silicon-barium multi-component alloy: Silicon-barium is a new type of multi-component alloy. Its advantage is that the content can be customized, and the silicon element inside can also be customized to make deoxidation more.

If you want to know more about the above products, please contact Hainan West Asia Group.