silicomanganese

Definition of Ferrosilicomanganese:

Ferrosilicomanganese is an alloy composed of manganese, silicon, iron, and small amounts of carbon and other elements. It is a widely used and high-production iron alloy. Silicomanganese is a commonly used complex deoxidizer in steelmaking and can be smelted in large, medium, and small ore-heat furnaces using continuous operations.

Classification of Ferrosilicomanganese:

The most commonly used varieties of ferrosilicomanganese are mainly designated as 6517#, with the standard grade FeMn68Si18.

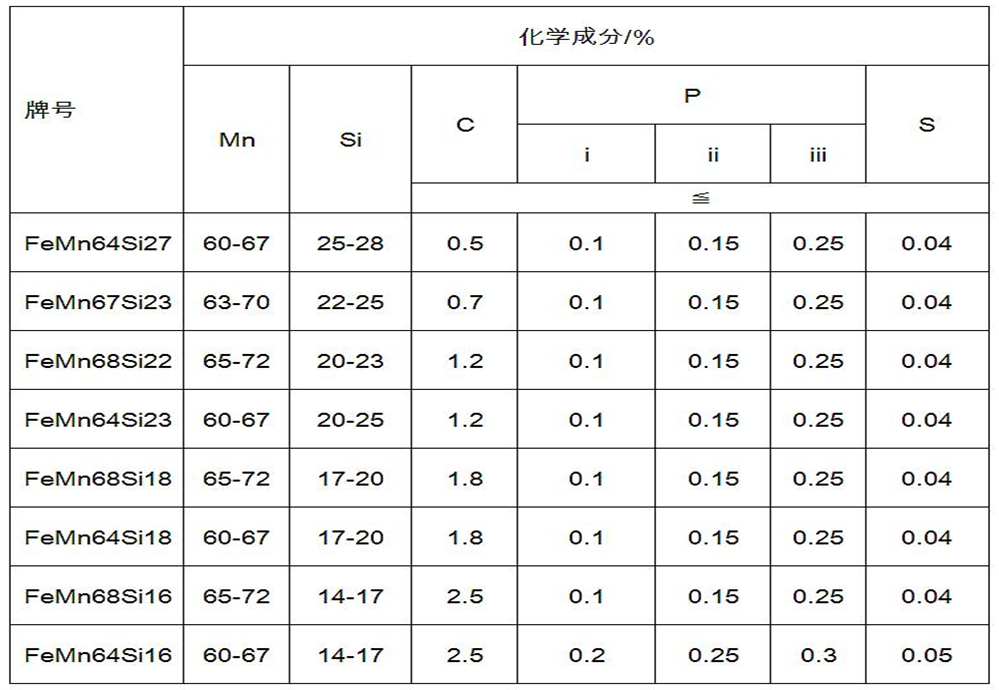

Ferrosilicomanganese is classified into 8 grades based on differences in manganese, silicon, and impurity content, with their chemical compositions as shown in the following table:

Table 1: Ferrosilicomanganese grades and their chemical compositions

Uses of Ferrosilicomanganese:

1、The main uses of ferrosilicomanganese are as a deoxidizer and alloying agent in steelmaking to eliminate excess oxygen and sulfur in the molten steel, thereby improving the quality and properties of the steel. It is primarily used as a deoxidizer. During steelmaking, processes like oxygen blowing are used to remove carbon, phosphorus, sulfur, and other harmful impurities from molten iron, which increases the oxygen content in the steel. Excessive oxygen content can reduce the mechanical properties of steel. Adding an element with a stronger affinity for oxygen than iron and whose oxides are easily removed from the molten steel in the form of slag helps remove oxygen from the steel, a process known as deoxidation.

2、The silicon and manganese in silicomanganese alloy have a strong affinity for oxygen. Using silicomanganese in steelmaking produces deoxidation products MnSiO3 and MnSiO4, which have melting points of 1270°C and 1327°C, respectively. This provides advantages such as a low melting point, large particle size, easy floatation, and effective deoxidation.

3、Silicon significantly improves the elasticity and magnetic properties of steel. Therefore, silicon-based alloys are used in the production of structural steel, tool steel, spring steel, and transformer steel. Typical silicon content in various types of steel ranges from 0.15% to 4.00%.

4、Manganese reduces the brittleness of steel, improves its hot working properties, and enhances its strength, hardness, and wear resistance. Manganese is indispensable in the production of high-quality steel, as it helps remove impurities like sulfur and oxygen during the steelmaking process, thus improving the physical properties of the steel. Currently, there is no other element that can replace manganese in its role in the steelmaking process. Manganese accounts for over 90% of the consumption in the steel industry, and it is considered a fundamental raw material for producing high-quality steel.